Manufacturer for Feed System Parts - Dimension of Feeding System – Egebjerg Detail:

Dimension of the feeding system

When determining the dimensions of a feeding system always consider that:

|

• |

The life time depends on hours a day the system runs |

|

• |

Larger feed tubes ensures a homogenous feeding |

|

• |

The system should run a maximum of 8 hours a day in peak periods |

A feeding system has a minimum of 7 corners. If the system is to have more than 7 corners, its length will decrease by 10 metres for every extra corner.

If e.g. the system has more than 12 corners the maximum length is 250 metres. If the feed string is to be longer two or more feeding system are necessary. Note, that as a rule-of-thumb four corners and ten metres length are necessary to transport the feed from the silo to the barn.

Product detail pictures:

Related Product Guide:

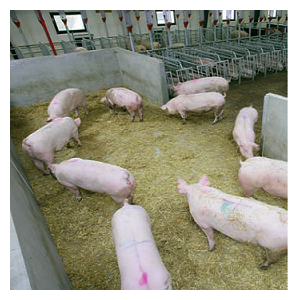

Inventions Competition 2019: Simple ideas for sheep and pig farmers | Mating Stall

Harmonious symmetry, shapes and consistency balance a manicured garden in Mount Baker | Water Trough

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Manufacturer for Feed System Parts - Dimension of Feeding System – Egebjerg, The product will supply to all over the world, such as: Barbados , Florida , Italy , "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

China OEM Feeding Pan - INN-O-STALL®FREE ACCES...

-

Professional China Frp Feed Bin - INN-0-CRATE ...

-

factory customized Automatic Pig Water Drinking...

-

Fast delivery Milk Feeding System - Stainless ...

-

Good Quality Feed Bin - Gavalnized Feed Silos ...

-

Factory Free sample Hog Feeder - SS201 Nipple ...